Flint Systems is proud to announce the completion of the second and final stage of the order for the Naval Port Command in Gdynia, delivering the innovative WELES welding simulator with a unique underwater welding capability.

In 2024, Flint Systems delivered two advanced WELES welding simulator sets to the Naval Port Command in Gdynia. These simulators enable training in four key welding methods: GMAW (MIG/MAG), SMAW (MMA), GTAW (TIG), and FCAW. They allow practice with various electrodes and materials such as stainless steel, carbon steel, aluminum, and copper, on sheets ranging from 2 to 20 mm in thickness. Thanks to virtual reality (VR) technology, the training is safe, cost-effective, and remarkably realistic.

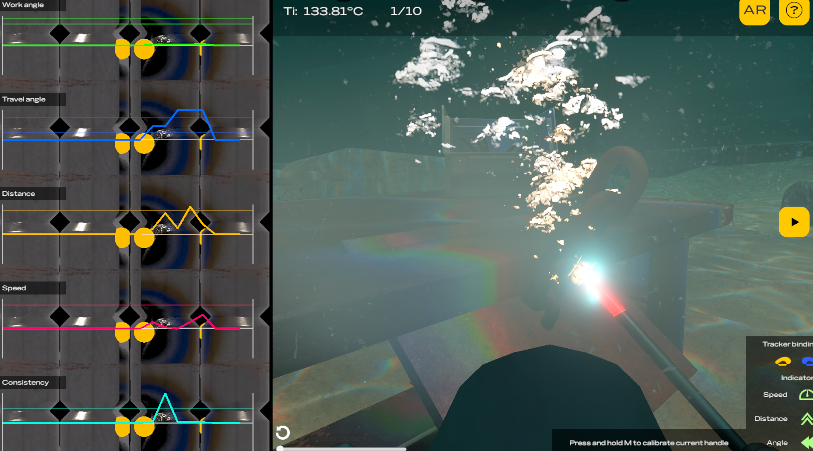

As part of the second stage of the order, completed by the end of May 2025, Flint Systems introduced a groundbreaking innovation – an underwater welding and oxygen lance cutting module, including the simulation of welding and cutting anchor chains.

A revolution in welding training

The new underwater technology module was developed in collaboration with experts to meet the specific needs of the Polish Navy. The WELES simulator allows trainees to improve their skills in realistic conditions while eliminating the risks and costs associated with traditional training methods. This solution not only enhances learning efficiency but also opens new opportunities for the maritime and shipbuilding industries.

“We are extremely proud to be the first in the world to deliver an underwater welding and cutting simulator, thus strengthening the Polish Navy. For our company, this is another step toward revolutionizing welding training,” said Leszek Tarnawski, CEO of Flint Systems.

Why is this a breakthrough?

Realism: The simulation accurately reflects the conditions of underwater welding and cutting, including the specifics of working with anchor chains.

Safety: VR training eliminates the risks associated with working in difficult conditions.

Cost-effectiveness: No need for real materials and equipment significantly reduces costs.

Versatility: The simulator supports various materials and techniques, adapting to the user’s needs.