With the environment in mind we aim to reduce CO2 emissions. With the current developing and expanding importance of hydrogen in the world, should not current technological solutions be developed and adapted to use hydrogen? In time natural gas will be gradually eliminated and replaced by 100% hydrogen. It is time to prepare for this change.

Hydrogen can be used as a fuel in combustion chamberin gas turbines. Alone or mixed in various volume proportions with natural gas. Advantageous technological solutions are being sought to achieve high efficiency of equipment and technology.

Modern gas turbines are already adapted to operate with a significant content of hydrogen in the mixture of gases burned, however the gas turbine industry has made a firm commitment to develop 100% hydrogen gas turbines by 2030. Thereby they fully supporting the transformation of Europe's renewable gas network by overcoming technical challenges and ensuring that this transformation takes place quickly [1,8].

Blending hydrogen with natural gas improves the use of hydrogen produced on a small scale to end users, promoting the decarbonization of the gas system [6].

Parameters and characteristic of hydrogen and natural gas

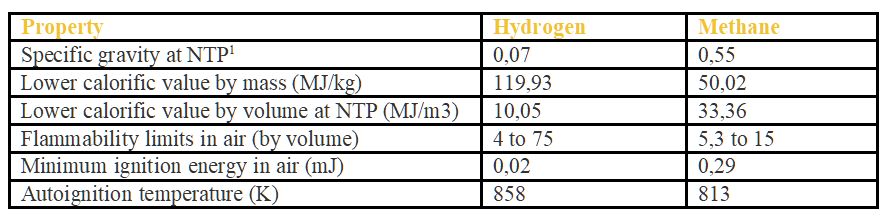

There are several important differences between hydrogen and natural gas. The Table 1 shows selected properties of hydrogen and methane (as the main component of natural gas).

Table 1. Thermophysical and chemical properties of hydrogen and methane [6]

1) NTP Normal Temperature and Pressure, i.e., 20 °C and 101325 Pa.

Unfortunately, because the physical and chemical properties of hydrogen differ significantly from those of natural gas, it is not possible to simply exchange natural gas for hydrogen.

The suitability of hydrogen for energy production is mainly determined by its calorific value. Compared to methane, hydrogen contains 2 times more energy per unit mass, but 3 times less per unit volume. In other words, as hydrogen blending increases, the average calorific content of the blended gas falls, and thus an increased volume of blended gas must be consumed to meet the same energy needs [1,4]. Therefore, a mixture of hydrogen and natural gas will have a lower energy content than the same volume of pure natural gas [7].

Blending hydrogen with natural gas

When it comes to use a mixture of hydrogen and natural gas, the main combustion properties (calorific value, Wobbe number) and other parameters of the formed mixture of natural gas and hydrogen should meet national regulations/specifications for natural gas. This will allow you to determine the actual amount of hydrogen to be mixed with natural gas [6].

There are some hydrogen combustion characteristics that differ from those of natural gas. Therefore, when using a mixture of hydrogen and natural gas it is important to consider that [7-9]:

Auto-ignition: Higher risk of auto-ignition due to lower ignition delay time. The high reactivity of hydrogen increases the risk of auto-ignition in the pre-mixing section. This can be particularly challenging in some systems with very high air inlet temperatures, such as in modern high-efficient gas turbines or micro gas turbines (due to the recuperator). To protect burners and fuel injectors from overheating or damage, burners are typically instrumented with thermocouples if more reactive fuels are used.

Flashback: Higher risk of flashback due to higher flame speed or lower ignition delay time. Burning hydrogen-rich fuels increases the risk of flashback due to the higher flame speed or because of the shorter ignition delay time compared to natural gas. This can be particularly challenging in some systems with very high inlet air temperatures.

Modified thermoacoustic amplitude and frequency levels. Hydrogen flames compared to natural gas flames, exhibit significantly different thermoacoustic behaviour. This is due to higher flame speeds, shorter ignition delay times and different flame stabilization mechanisms, which resulting in different flame shapes and different reactivity.

Increased NOx emissions. The higher adiabatic flame temperature for H2 will result in higher NOx emissions.

Higher pressure drop due to lower Wobbe number. When burning hydrogen, a higher volumetric flow rate of the fuel is needed due to its lower volumetric heating value (LHV). Hydrogen has a lower Wobbe number (WI) which is the most widely used parameter for specifying the acceptability of a gaseous fuel in a combustion system. The meaning of the Wobbe number is that for a given fuel and burner supply conditions (temperature and pressure), two gases of different composition, but with the same Wobbe number, will give the same energy contribution to the combustion system.

Reduced life/need for greater cooling of hot gas path components due to increased heat transfer. Burning hydrogen instead of natural gas will increase the moisture content of the exhaust gas. Hot corrosion will be likely to occur.

Is there a safety risk in blending hydrogen? Consider the following [4]:

Hydrogen has a lower LEL than natural gas, so there is a greater risk of creating a flammable atmosphere when mixing gas mixtures.

Hydrogen has a lower ignition energy than natural gas and a wide flammability range (from 4% to 74% in air), so there is a greater risk of explosion.

Hydrogen molecules are small and move quickly, so any leakage of the gas mixture will spread faster and more widely than would happen with natural gas.

Turbine

The challenges for hydrogen-fueled gas turbines and the problems that need to be solved as a result are in particular the reduction of NOx. In the development of hydrogen gas turbines, a key technology is stable and low NOx hydrogen combustion, especially dry low emission (DLE) or dry low NOx (DLN) hydrogen combustion. Due to the large difference in the physical properties of hydrogen compared to other fuels such as natural gas, well-developed gas turbine combustion systems cannot be directly applied to DLE hydrogen combustion. Thus, the development of DLE hydrogen combustion technology, elimination of combustion chamber oscillations, and elimination of flame jumps are an important and challenging tasks for the future of hydrogen-fueled gas turbines [3,5].

Dry Low Emission (DLE) technology has the potential to enable flexible fuel operation in the 0-100% H2 range with low emissions.

Smaller hydrogen contents, i.e. 10-30 percent by volume, do not require modification, although this ultimately depends on the type of turbine. The addition of hydrogen up to 50 percent or even 70 percent may mean modifications to the burner and control systems for combustion control and safety [2].

In order to develop a hydrogen-fueled gas turbine block, other equipment must also be considered in parallel with the development of the combustion chamber. Since modern gas turbines run mainly on natural gas, material specifications for piping and other auxiliary systems are currently being selected on the assumption that they will use natural gas [3].

Hydrogen, compared to natural gas, diffuses more easily through the components of the facility's equipment, so it is necessary to develop safety solutions adapted to the properties of hydrogen and to reselect the appropriate specifications. Due to the higher volumetric flow rate, it becomes necessary to use larger diameters in fuel supply systems when using hydrogen [3].

A glance at some of developing solutions

Mitsubishi Power has already successfully completed a bench test of co-combustion of 30% hydrogen in a dry combustion chamber with low NOx emissions in 2018. The next stage of research and development is to develop a dry burner with low NOx emissions for operation with 100% hydrogen. The bench test should be successfully completed around March 2025 [3].

Typical combustion systems with low NOx emissions can use a mixture of only methane with a relatively small amount of hydrogen. Modified systems are required to burn larger amounts of hydrogen. This technology has long been mastered by leading gas turbine manufacturers, including General Electric, which offer an operating range from 5 to 100% hydrogen content.

In the Kawasaki hydrogen technology developments, hydrogen gas turbine and hydrogen combustion technologies have been developed. The commissioning of the world’s first diffusion flame combustor with 100% hydrogen-fueled gas turbine has been carried out successfully in Kobe, Japan [5].

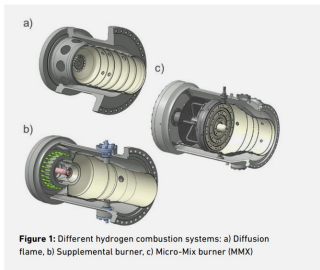

Kawasaki Heavy Industries has overcome Dry Low Emission (DLE) challenge by developing 3 different H2 combustion systems [5]:

The diffusion flame combustor in Figure 1a can operate with 100% hydrogen and 100% natural gas, as well as mixtures of both fuels. Water injection is used to achieve low emissions.

In Figure 1b, the second solution is shown, which is based on a conventional DLE combustor with hydrogen injection through a supplemental burner up to 60% hydrogen, corresponding to 30% of the total thermal output.

Within this burner it is possible to switch from natural gas to hydrogen or from a mixture of natural gas and hydrogen to gaseous fuel through the supplementary burner. NOx emissions can be kept below a guaranteed level of 25 ppm (O2-15%).

The use of hydrogen in conventional DLE burners increases NOx emission values, as well as the risk of ignitions.

Therefore, an innovative Micro-Mix DLE combustor (MMX combustor) has been developed by applying an interactive optimization cycle including experimental and numerical testing on test burners and full scale testing of the combustion chamber - Figure 1c [5].

Summary

The use of natural gas is resulting in significant emissions of greenhouse gases and pollutants into the environment. Hydrogen provides a possible alternative as a fuel for gas turbines in the future low carbon power industry.

Hydrogen technologies with Eko-Konsult

Due to the specific properties of hydrogen, advanced process parameters, and legal requirements, many different analyzes are necessary to obtain the legal safety approval of hydrogen projects.

Based on the experience gained in the hydrogen installations industry, Eko-Konsult offers a variety of specialized services dedicated to investors, design offices and general contractors. We can support your hydrogen project with:

Feasibility studies of hydrogen installations

Determining the safe distance of hydrogen installations from buildings, public roads, etc. (e.g. QRA risk analyzes)

Environmental reports and project information sheets

Establishing process protections and interlocking functions (HAZOP and SIL analyzes)

Determination of the safe location of hydrogen blasts (analyzes of dispersion and thermal impact ranges)

Classifications of explosion hazard zones and explosion risk analyzes

Determining the conditions of fire protection

Development of documentation for plants with an increased and high risk of a major industrial accident (Seveso III Directive)

Trainings

The hydrogen transformation cannot take place without qualified staff, therefore, as part of the Hydrogen Academy, we conduct numerous training courses related to this subject, for example:

Safety rules on hydrogen installations

Fire and explosion safety at the design stage of hydrogen installations

Process safety in hydrogen installations

Hydrogen detection systems

Can we support your hydrogen project? Please do not hesitate to contact us.

Review by Aleksandra Wawrzyniak

References

1. P. Olszowiec, Turbiny gazowe na… wodór, Energia Gigawat, (11-12/2020)

2. https://wysokienapiecie.pl/34759-turbiny-na-wodor-pojawia-sie-na-rynku-w-przyszlosci/ (access date: 8.10.2022)

3. J. Klebes Mitsubishi Power Europe, Duże turbiny gazowe umożliwiające zastosowanie wodoru, Nowa Energia, 2(78)/2021

4. https://www.crowcon.com/blog/how-hydrogen-is-helping-the-gas-and-steel-industries-to-go green/ (access date: 8.10.2022)

5. N. Tekin, M. Ashikaga, A. Horikawa, H. Funke, Enhancement of fuel flexibility of industrial gas turbines by development of innovative hydrogen combustion systems, Gas for energy, Issue 2/2018

6. J. Beita, M. Talibi, S. Sadasivuni, R. Balachandran, Thermoacoustic Instability Considerations for High Hydrogen Combustion in Lean Premixed Gas Turbine Combustors: A Review, Hydrogen, 2, 2021

7. Hydrogen quality for blending with natural gas. Technical recommendations, June 2022 https://www.marcogaz.org/ (access date: 8.10.2022)

8. ETN Global. Hydrogen Gas Turbines. Report, 2020

9. Taking DLN gas turbine hydrogen blending to the next level (power-eng.com) (access date: 8.10.2022)