Jan Gortatowski and his company Fem4Cad were practically at the dawn of Polish offshore, when no one saw it as a business. They have watched the industry grow from a front-row seat. And although they have long proven to the doubters that they can be an important element of the supply chain in the construction of, for example, installation ships, in Polish offshore they are still a spectator, not a participant – like the entire shipbuilding sector.

It would seem that the company,

which is involved in design work on the largest and most technically

advanced installation ships at the time, would be one of the first

addresses to which the largest players in the Polish offshore wind

energy industry will direct their steps. After all, they must

organize themselves in such a way that they will be able to implement

several projects at sea within a dozen or so years. However, the

Gdynia-based company Fem4Cad participates in the offshore market, but

not yet in the domestic market. Our domestic shipbuilding industry

has been almost entirely omitted from the offshore market, and

installation ships will come from other countries.

– My colleagues from the time I

worked at the Gdynia Shipyard dreamed of designing and building an

aircraft carrier (laughter). I would like to design and build a

jack-up – says Jan Gortatowski when we talk in the Fem4Cad office.

Beginnings

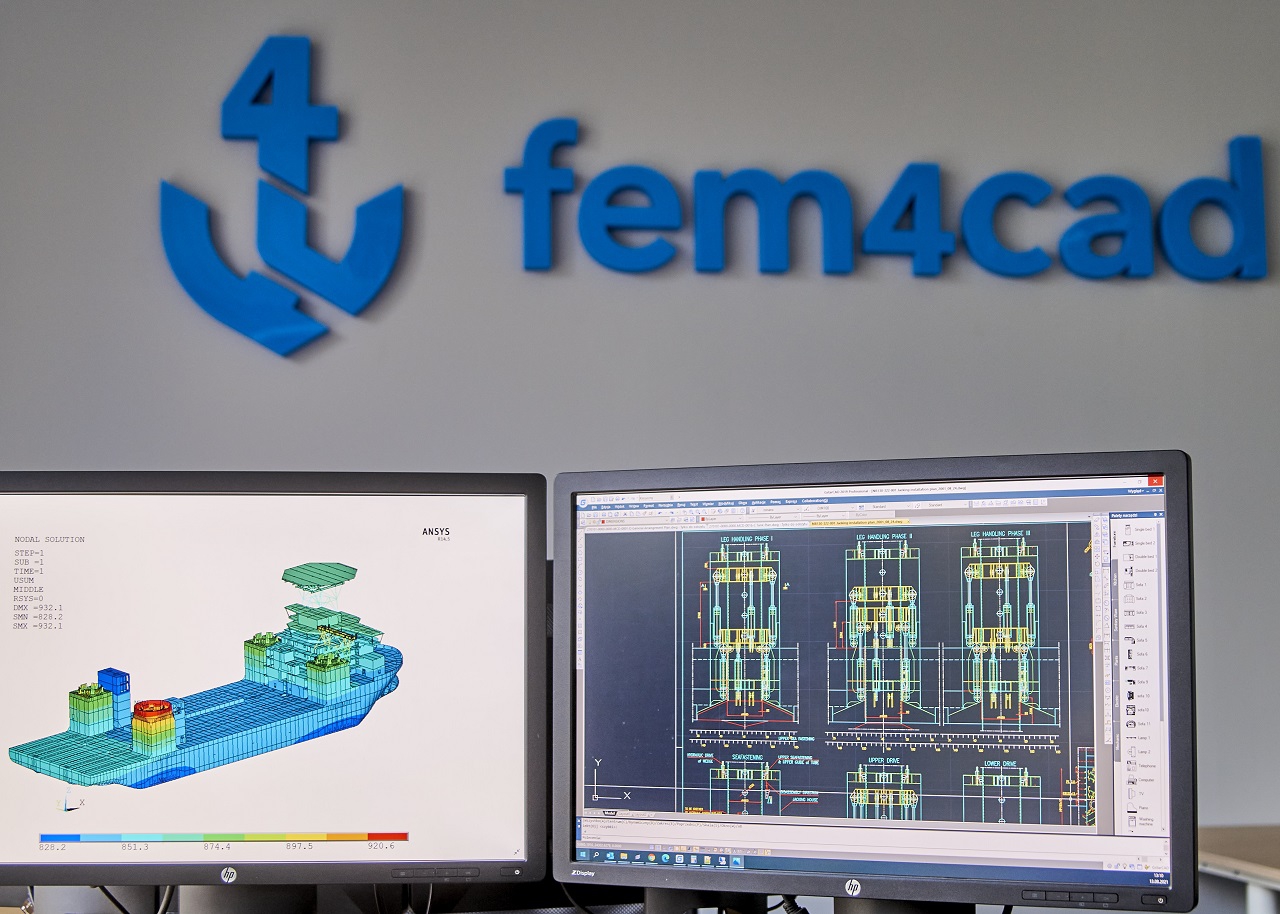

Fem4Cad,

as Gortatowski himself says, supports design offices in specific

types of calculations and simulations necessary to complete full

construction or reconstruction projects of ships.

– The analyzes we deal with in

the case of offshore vessels are mainly analyzes related to the

durability of these vessels, but there are more problems with such

vessels, so we also deal with other types of simulations. It used to

be that we could say that we performed strength calculations, but

currently there is no good definition of what we do. That's why I

often say that we deal with simulations. Using numerical methods, we

analyze issues that we may have problems with on vessels, starting

from hydrodynamic analyses, through strength and fatigue

calculations, then vibrations and, for example, noise forecasts... –

explains Jan Gortatowski descriptively. – We operate in the broadly

understood marine & offshore industry. The projects we implement

come from virtually every part of this large market – he sums up.

The company itself was established

on the basis of another one, in which Jan Gortatowski was the head of

the Marine & Offshore department. However, the business was taken

over by a larger organization from the automotive industry, so the

unit design department was separated and began to function

independently. In this way, it filled the gap left by the dissolution

of very large design departments in shipyards. Their task was to

support production. However, the private offices created on their

basis had to focus on making money. They could not afford to maintain

teams of several hundred people. Therefore, gaps were created in this

field that could be filled by small but highly specialized teams,

like Fem4Cad. It's no wonder that the vast majority of it's employees

has been working together for 15 years.

– We wanted to support design

offices in the most difficult specialist issues related to broadly

understood calculations – says Jan Gortatowski. That is why

Fem4Cad's direct clients are design offices that subcontract complete

or partial analyzes of projects carried out for their clients to the

company.

Waiting for Polish offshore

Jan

Gortatowski says directly that his company has plenty of work, but

during the conversation we inevitably talk about Polish offshore.

Fem4Cad was one of the few Polish companies that cooperated in the

design (and subsequent redesign) of several high-profile offshore

vessels, so it is no wonder that Gortatowski and his team kept their

fingers crossed for the development of Polish offshore wind energy.

It could bring them important orders and give them the opportunity to

consolidate their position in the supply and development chain.

– We were very much involved in

the creation of the offshore market while working in the previous

company – recalls Jan Gortatowski. He adds that the first ideas for

organizing Polish offshore appeared right after the implementation of

the Vidar installation ship project, on which engineers from Fem4Cad

cooperated with its designer, StoGda, and which was built in the

Crist shipyard in Gdynia.

– A very nice ship was built,

with which the shipowner was very satisfied. Back then, people were

just starting to talk about Polish offshore, but no one wanted to

invest yet – says Gortatowski. He mentions a number of initiatives

that involved, among others large Polish companies. The projects

sometimes dissolved over time, sometimes crashed due to simple

problems, sometimes disappeared from desks along with personnel

changes. – I remember the first meetings of PTMEW (Polish

Offshore Wind Energy Society – red.) It was said that, taking

into account our potential in the offshore industry, we could have

our local content at the level of 70%, maybe even 80% with good

management... Currently, it is said to be 5%...

The potential therefore remains

untapped. As Gortatowski points out, it is not only about his

company, but also about the entire shipyard and design industry.

– As for our company, we

cooperated with StoGda on all projects related to installation ships.

It was Vidar, and on the way also Zourite – although it was not a

vessel for installing wind farms, it was also a jack-up. Then we

participated in the Voltaire project together. This is the largest

ship built by Jan De Nul. In the meantime, we were making upgrades on

existing ships, mainly on Vidar, which is now called Vole au Vent

after a change of shipowner. Practically once a year we had a task

related to changing the field in which we operate or other

reconstruction resulting from current operation. Therefore, it seems

that when it comes to installation vessels, we could freely design

and build them on our market – says the head of Fem4Cad. However,

he points out that no company has been established in Poland that

could manage this type of ship, although there have been several

attempts. – I think that if there was only good will on the part of

potential operators of Polish offshore wind farms, such as PGE, Orlen

or Polenerga, a ship dedicated to the conditions of the Baltic Sea

could be designed and built for a Polish shipowner. Virtually all

countries around the Baltic Sea are interested in offshore wind

farms. I think that such an investment could not fail to pay off.

The lack of orders from Poland does

not mean that Fem4Cad has no orders at all. The topic of installation

ships returns to the desks of employees of the Gdynia office from

time to time.

– New generation ships are

designed a bit more universally, but Vidar-class ships were designed

for the conditions of a specific field. The ship works in a field for

a year or two, then moves to another one. The conditions in which the

vessel operates change, for example the type of ground on which it

will stand. This means that something constantly needs to be

redesigned and changed – explains Jan Gortatowski. – One of such

large reconstructions in Vidar was the relocation of chimneys. In the

first version, the chimneys were placed symmetrically, on the

starboard and port sides. But on the starboard side, on the rear leg,

we had a crane installed. The smoke from the chimney disturbed its

operator. So it was decided to move all exhausts to the port side. It

was a large reconstruction that took place at the Nauta Shipyard in

Gdynia – he says.

Technology is also constantly

changing. The power of wind turbines is increasing, and the

foundations are growing. All this requires increasingly larger ships

with increasingly greater capabilities.

– When Voltaire was built, he was

able to guarantee the installation of all possible types of

foundations existing at that time. The ship has a crane capacity of

3,000 tons and is able to operate at a depth of 80 meters. These

parameters have never been seen before. And now it is already being

said that 3,000 tons may not be enough. The Chinese are talking about

turbines above 20 MW... Shipyards and design offices have to keep up

– notes the head of Fem4Cad.

Offshore is not everything

Although

Fem4Cad has experience and competences in the field of installation

vessels and other jack-ups that could significantly facilitate the

construction of offshore wind farms in the Baltic Sea, its

capabilities do not end there. Therefore, the company does not intend

to wait idly for potential orders from Polish offshore.

– We're not complaining. We

really have a lot of work to do. We would love to take part in the

construction of a Polish jack-up, but we are not sitting idle.

Currently, we have been working on new car carrier projects for

almost three years. This is a reviving market – says Jan

Gortatowski. He recalls that Poland used to be a leader in the design

and construction of this type of ships. Currently, they are about 25

years old, so it is time to replace this fleet. However, they are

currently made in China. – Fortunately, their projects are still

being created in Europe. In the case of car carriers, our direct

client is the Deltamarin design office from Finland – adds

Gortatowski.

Fem4Cad is also active on the oil &

gas market, where the FPSO ship sector has emerged. Over the last few

years, the company has conducted several crash analyses.

– This is a bit unusual in our

industry, we rarely hear about "crashes" in traditional

vessels. However, in the case of FPSO units, this is a fundamental

problem. These vessels are moored and filled with oil or its

derivatives. Service ships or ships receiving or delivering crude oil

dock there all the time. Therefore, there is a great risk that such a

ship will collide with the side of the FPSO – describes

Gortatowski.

In this case, the company performs, among others: "crash" analyzes necessary to design protective structures for equipment elements mounted on FPSOs. All this is done by 8 Fem4Cad employees and, if necessary, 4 collaborators.

– We have been working together

continuously for 15 years. No one from this team left during this

time, except for one person who completely changed the industry.

There were situations when we could have had even more work, but then

we told the client honestly that either we would do it later or,

unfortunately, we would not be able to quickly increase the

processing capacity, for example twice, because we could not do it

responsibly. Our team consists of experienced specialists, the likes

of which are simply few on the market – explains Gortatowski.

During the six years of work under

the Fem4Cad banner, this well-coordinated team had the opportunity to

take part in large, high-profile projects in the maritime industry.

Which of them make Jan Gortatowski most proud? In response, he

mentions the car carrier project carried out a year ago for

Deltamarin. It is a modern vessel, very large, for 9,000 cars.

Fem4Cad performed an almost complete strength analysis for this

project. Currently, the shipyards are working on three such ships in

parallel, and a total of a dozen of them are to be built, which

confirms that this is a good project. The head of Fem4Cad also

recalls the first order that the company completed immediately after

its establishment – the Ro-Pax project for the DFDS shipowner, for

which it also performed a complete strength analysis.

– We don't have much competition

at the moment, at least here, on our market, so the more difficult

the issue, the greater the satisfaction. During the 6 years of the

company's existence, almost every subsequent project was completely

different, it is difficult to find two identical topics, so we do not

have repetitive work, each subsequent topic is a challenge – says

Gortatowski.

At the very end, however, we return

to the installation ship. Considering the full schedule, would

Fem4Cad still be able to involve a Polish jack-up in the project?

– In fact, we currently have a

full workload for about half a year. If I received information today

that such a ship would be built, I could immediately say that the

project would not start before the end of the year. Then we are as

available as possible (laughter). There is no problem – concludes

Jan Gortatowski.