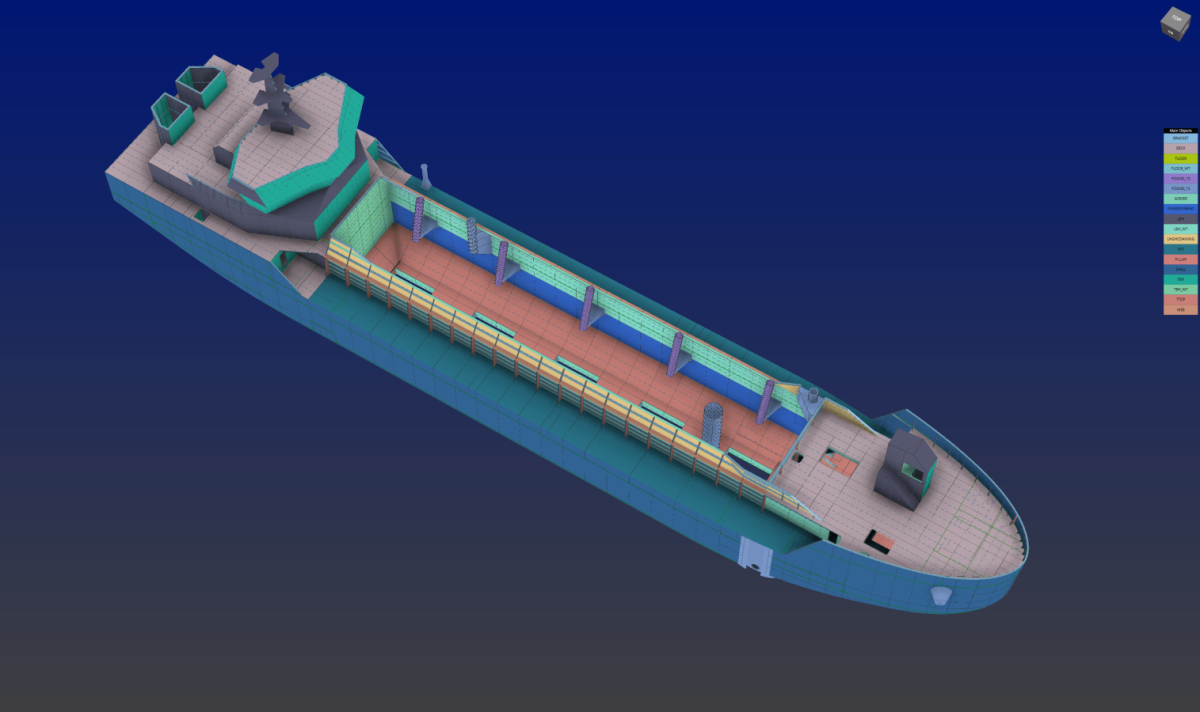

Damen Engineering Gdansk in cooperation with Napa and Bureau Veritas has approved the class design of the vessel based on a 3D model of the hull structure.

The hull structure design of

the Damen TSHD 1000 (Trailing Suction Hopper Dredger) ship made using

NAPA's specialized software has received class approval from Bureau

Veritas based on a 3D model.

3D modeling of a vessel is

commonly used at various stages of project development.

Differentiated 3D modeling is used by ship designers and engineers to

visualize hull geometry, strength and stability calculations of the

vessel. The 2D drawing generated from the 3D model is a common and

widely used information carrier in the ship design and production

process.

There are several steps in

the commonly accepted and functioning process in the industry. The

designer works with the 3D model, then translates this into 2D

drawings to obtain approval of the vessel's class. Once the 2D

drawing information is received, classification societies must

generate a new 3D model based on the 2D drawings provided to perform

independent calculations and provide their feedback on the 2D

drawings. Finally, in response to the society's comments, the

designer must translate the 2D drawings back into 3D to make changes.

In the new approach, 2D

drawings have been eliminated from the process. This was made

possible by using the OCX (Open Class eXchange) format in the various

neutrals.

The use of the OCX format

allowed the parties to optimize the process to save time, but also to

improve communication and facilitate collaboration between the

designer and the person responsible for approving the hull design.

The 3D tool used by Damen

Engineering is provided by the Finnish company NAPA. The Gdańsk

office has been using its software for many years, but the

integration of the OCX format in the tool has opened up the

possibility of exchanging data in a whole new quality.

The traditional process

limits creativity, slows down communication, forces the creation of

duplicate drawings, which increases the risk of mistakes.

Katarzyna

Romantowska-Jaskólska, managing director of Damen Engineering

Gdansk, said that the ability for all partners to review and approve

the same 3D model completely changes the rules of the game for ship

designers and classification societies, as well as for stakeholders

in the said process.

NAPA, together with a

consortium of companies supporting the development of the OCX format,

intends to bring OCX into widespread use.

Damen Engineering Gdansk

intends to apply and develop the approval of further vessels using

only the 3D model (3D Model Based Aproval process), also in

cooperation with the classification society DNV and others.

Part of the Dutch

shipbuilding group, Damen Engineering Gdansk was established in 2013.

It designs prototypes of specialized vessels.